EPDM Closed Cell Sponge Rubber

Expanded closed cell synthetic rubber

EPDM which is short for ‘Ethylene Propylene Diene Monomer’ is a flexible expanded closed cell synthetic rubber used in a wide range of applications. Most commonly used in the automotive and construction sector for roofing applications due to its high-density, ease of application and durability properties.

EPDM is made from a variety of chemicals, all of which vary in proportions, Ethylene being the largest proportion. The diene monomers are the smallest proportion of compounds which form EPDM closed cell sponge rubber. However, this chemical provides the cross-linking aspect that creates a high level of resilience, flexibility and longevity of this material. It is also flame retardant to conform with FMVSS302 standards.

The popularity of EPDM closed cell sponge rubber has increased significantly in recent years, mainly due to its excellent durability against abrasions, cuts and tears. The chemical composition of EPDM has created an extremely durable material with an extensive lifespan when compared with other materials. Here are just some of the different characteristics that make EPDM a superb choice for many tasks:

- Resistant to some chemicals

- Waterproof & Weatherproof (Sunlight, U.V.)

- Free from fibre or dust particles

- Unaffected by extended exposure of steam

- Temperature resistant between approximately 50c and 140c

- Vibration dampening

The unique properties of EPDM synthetic rubber, as well as the quality and low cost of this material, is what makes it a highly appealing choice for many applications, for example:

- Window & door seals

- Packaging & transportation

- Construction applications – radiators, doors, windows

- Automotive – aircraft, aerospace, ships

- Electrical insulators

- Playground surfaces

- Artificial grass

- Railways

Along with the diverse range of outdoor applications EPDM is suitable for, it is also a highly-rated product used in the automotive industry for numerous types of vehicles. The powerful components that create EPDM rubber, aside from its exceptional durability, are what make this the ideal material for automotive applications. Particularly for door & window seals, vibration dampening, overhead waterproof membranes and hoses & gaskets.

While EPDM has excellent resistance to many elements including U.V., ozone, alkalis, water, heat, steam and weather, it has proven to be less resistant to some oil-based products. Some of these include grease, petroleum-based products, hot bitumen and vegetable & mineral oils, all of which are should be avoided.

EPDM is typically available in rolls or sheets. However, these can be supplied in cut to size strips too. There are various thicknesses of EPDM that are available from as little as 1mm to 50mm in some cases. Specialist bespoke items such as gaskets, seals, tapes and coils can also be supplied.

Should you require any sizes, thicknesses or shapes that are not shown on our website, please contact us, and we will be happy to assist.

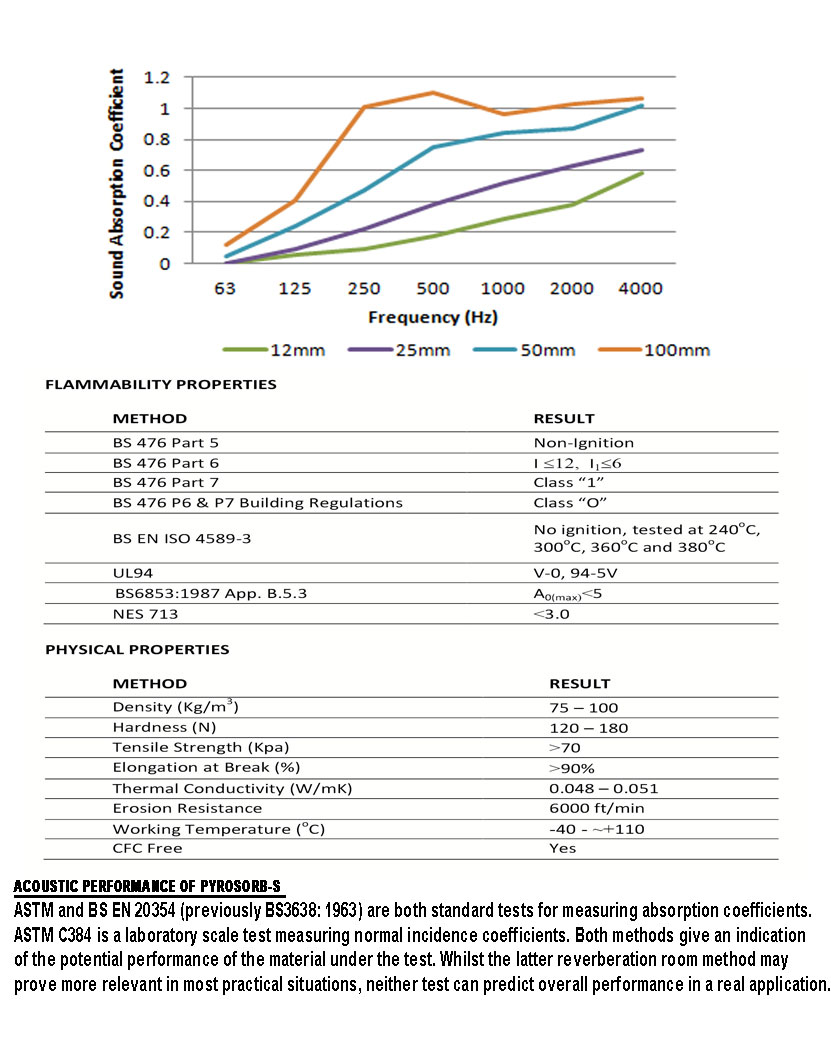

EPDM Closed Cell Sponge Rubber Foam Data

| Description | Standard |

| Colour | Black |

| Size - skin / skin | 2000mm x 1000mm x 50mm (±2mm) |

| Compression @ 25% Deflection (kPa) ASTM D1056 | 20-50 |

| Compression Deflection @ 50% (kPa) ASTM D1056-00 | 70-130 |

| Density (kg/㎥) ISO 845-95 | 90-140 |

| Compression Set (50% 22h) ASTM D1056-00 @ 23°C | <25% |

| Compression Set (50% 22h) ASTM D1056-00 @ 40°C | <80% |

| Water absorption, maxium change in weight (%) ASTM D1056-00 | <5% |

| Heat Ageing, Change in Compression Deflection, 168hrs @ 70°C | ± 30% |

| Flammability FMVSS 302 | Burn Rate < 100mm |

| Elongation at Break (%) | > 70% |

| Tensile Strength | >300kpa |

| Temperature Range (°C Low-High) | -40/+90 |

| Temperature High Intermittent °C | +100 |

| Resistance to Air and UV | Excellent |

| Resistance to Oil | Poor |

| Resistance to Acids | Good |

| Environmental Protection | CFC and HFC Free. Can be recycled |

| Specification ASTM D1056-00 AFNOR | 2A1/2 B2CP |

| Specification NF-R99-211-80 | 2CO8 B3 C2 |

Figures quoted above are average values.